The Evolution of Industrial Robots: From Assembly Lines to Sustainable Manufacturing

Industrial robots have come a long way since their introduction on assembly lines in the mid-20th century. Initially designed to increase productivity and reduce human labor in repetitive tasks, these machines have evolved into sophisticated, intelligent systems that play a crucial role in modern manufacturing. Today, they are not just tools for efficiency but also key players in the drive toward sustainable manufacturing.

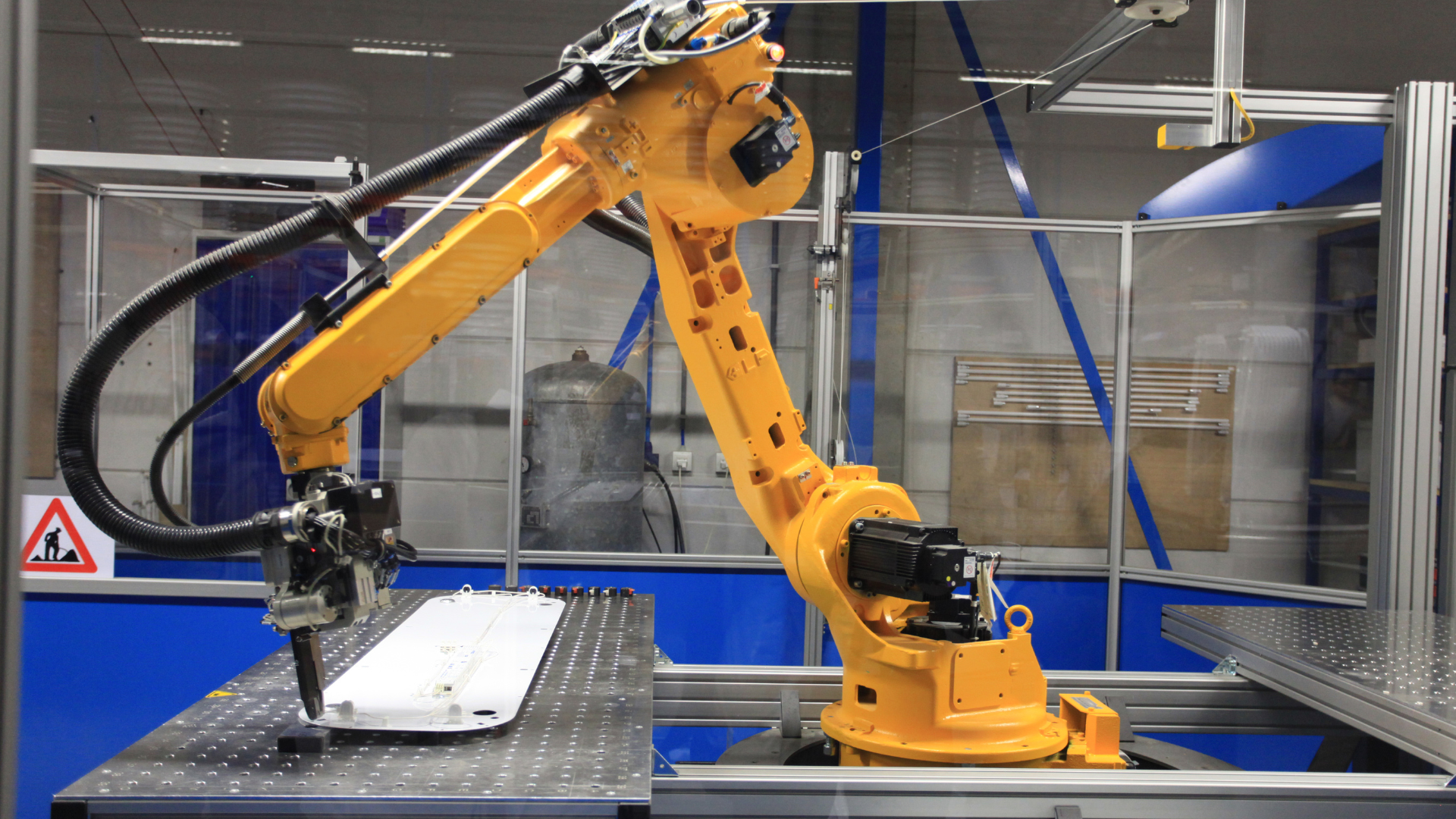

The journey of industrial robots began in 1961 when Unimate, the first robotic arm, was installed at a General Motors plant. This pioneering robot was tasked with moving hot metal parts—a job too dangerous and tedious for human workers. Unimate’s success sparked interest across industries, leading to the gradual adoption of robots in manufacturing processes. These early robots were simple and limited in functionality, but they laid the foundation for the advanced robotics we see today.

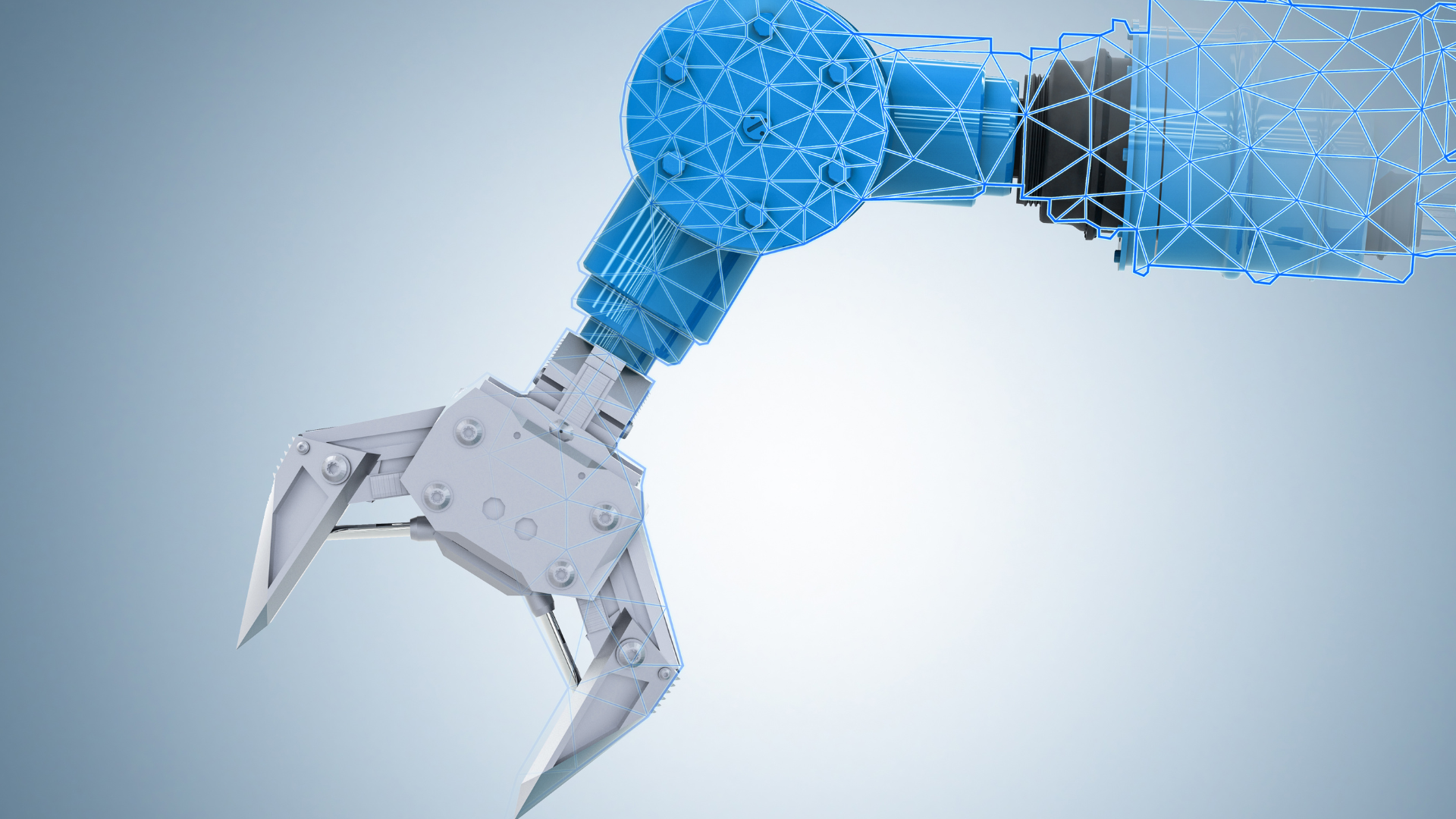

As technology advanced, so did the capabilities of industrial robots. The introduction of sensors, computer vision, and artificial intelligence allowed these machines to perform increasingly complex tasks with greater precision. By the 1980s, robots were being used not only in automotive manufacturing but also in electronics, aerospace, and consumer goods production. They could now assemble delicate components, perform quality inspections, and even handle hazardous materials, all with minimal human intervention.

The role of industrial robots has further expanded in the 21st century, particularly with the growing emphasis on sustainability. Modern robots are designed to be energy-efficient, using less power while performing tasks faster and more accurately than ever before. They also contribute to sustainable manufacturing by minimizing waste. Robots can be programmed to use materials more efficiently, reducing scrap and lowering the environmental impact of production processes.

Moreover, industrial robots are now integral to the adoption of green technologies. In industries like renewable energy, robots are used to assemble solar panels, wind turbines, and electric vehicles, helping to accelerate the transition to a low-carbon economy. They also support circular economy practices by aiding in the disassembly and recycling of products at the end of their life cycles.

The evolution of industrial robots is a testament to the transformative power of technology in manufacturing. From their early days on assembly lines to their current role in sustainable manufacturing, these machines have continually adapted to meet the changing needs of industry. As the push for sustainability intensifies, industrial robots will undoubtedly continue to play a pivotal role in creating a more efficient and environmentally friendly manufacturing landscape.